Thu Feb 19

Diamond grinding wheel

2022-07-11

2022-07-11

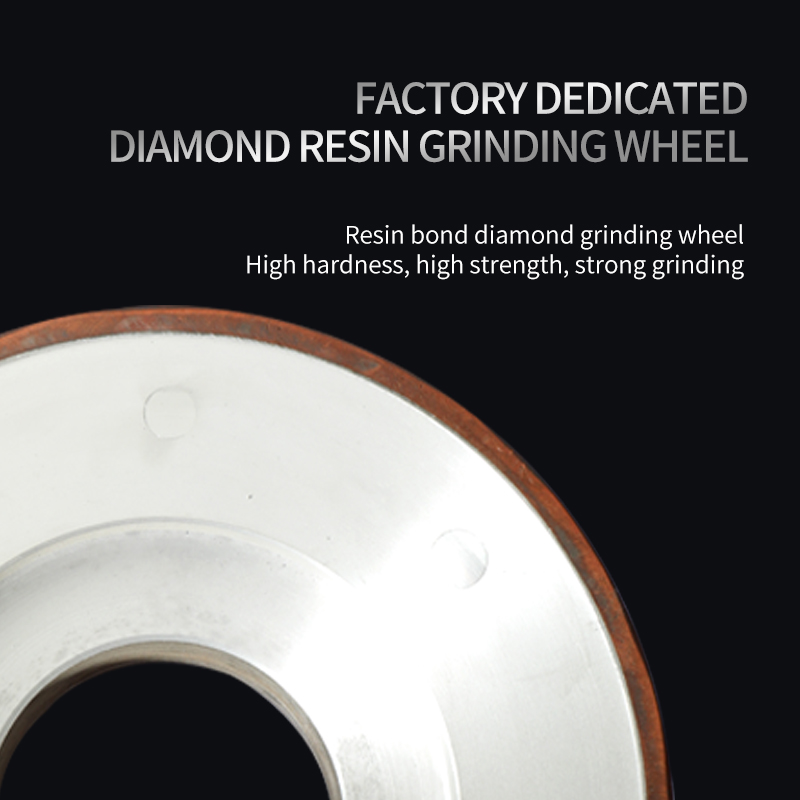

Due to the characteristics and advantages of diamond abrasives, diamond grinding wheels have become the ideal tool for grinding hard and brittle materials such as glass, ceramics, gemstones, stone, and carbide. With the progress of the times, the development of science, the needs of society, the development of new materials, and the continuous development of grinding processing in the direction of high quality, high precision, high efficiency and automation, the role of diamond grinding wheels is becoming more and more obvious. The diamond grinding wheel has high holding strength for abrasive grains, long life and low wear, so that the diamond grinding wheel can give full play to its strong wear resistance and cutting ability in high-speed and ultra-high-speed, high-efficiency and high-precision grinding, especially in hard, brittle and difficult machining. The material shows its obvious advantages and is widely used. Diamond grinding wheels are used in almost all sectors of industry, such as aerospace, mold manufacturing, semiconductor manufacturing, and optical processing manufacturing. Ceramic materials, optical materials, aero-engine turbine blades, silicon wafer products, etc. are mostly ground with diamond grinding wheels.

Diamond grinding wheel is a super-hard abrasive grinding wheel. Compared with ordinary abrasive grinding wheel, it has very obvious features and advantages:

1. The hardness of the diamond abrasive determines the main characteristics of the diamond grinding wheel, which can efficiently grind hard alloys, glass, ceramics and other difficult-to-machine materials, and the grinding tools have the longest service life.

2. Diamond has high wear resistance, the grinding wheel wears less, and the use time is longer. During grinding, the size, shape and morphology of diamond abrasive grains change little, which is more suitable for high-precision machining and production. High efficiency, diamond grinding wheel is a tool that can satisfy both high efficiency and precision machining.

3. The sharpened diamond grinding wheel can maintain the micro-edge of the abrasive grains for a long time, and the good cutting performance ensures a small grinding force during the grinding process, thereby reducing the grinding power and saving energy.

4. The thermal conductivity of diamond is very good, which is conducive to the evacuation of heat, avoiding the phenomenon of workpiece burns, cracks and falling blocks, which greatly improves the quality of workpiece surface processing.

Sichuan Changhao Diamond Products Co., Ltd. is a high-tech company integrating research, development and production of superhard abrasive products. Specializing in the production of ceramic, resin, metal bond superhard abrasives.

The main product types are ceramic-bonded CBN grinding discs, diamond grinding discs, ceramic-bonded CBN grinding wheels, diamond grinding wheels, cutting fluids, metal cleaning agents, and super-molded hard tools.

The company establishes a quality assurance system in accordance with the requirements of market standards; with an excellent professional team and advanced production and testing equipment, it ensures high-quality pre-sale, in-sale and after-sale services. Based on the concept of "integrity, innovation, refinement and service", Changhao people have won the trust and recognition of friends from all walks of life with exquisite technology, advanced technology, high-quality products and perfect services.

Xiangjun Li

344110978@qq.com

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.