Thu Feb 19

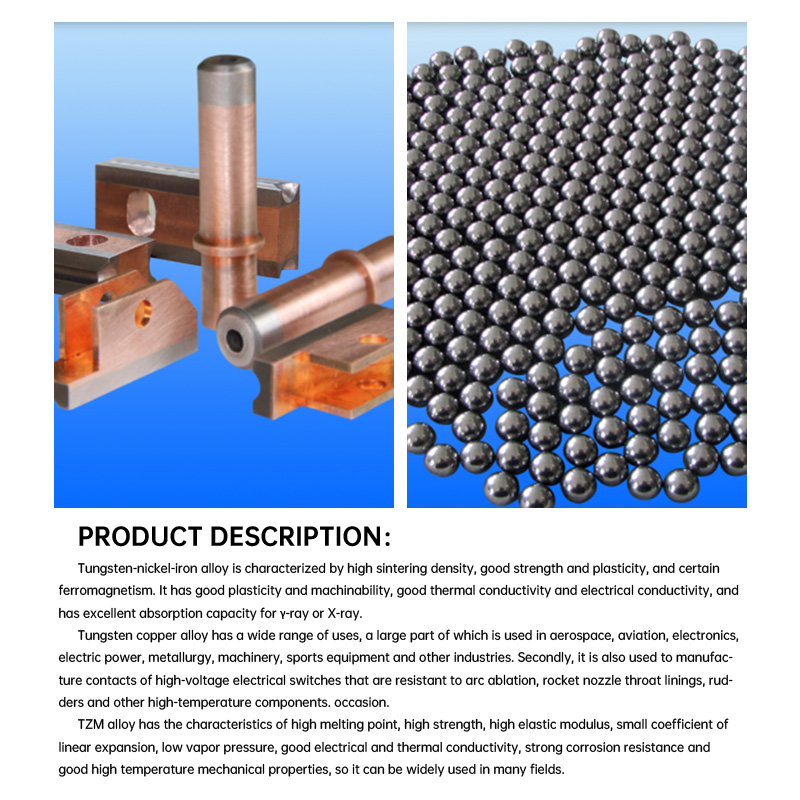

Tungsten Nickel Iron, Tungsten Copper Alloy, Tzm, Molybdenum Fund High Specific Gravity, Tungsten Based High Specific Gravity, Molybdenum Alloy, Tungsten Alloy

2023-03-13

2023-03-13

Product role.

1. In modern combat, the main target of attack is tank armor, strong fortifications and protected combatants, in order to obtain a fatal blow effect, high density, high storage speed, strong penetration ability, high performance materials are indispensable, the tungsten-based high specific gravity alloy counterweight parts manufactured by our company are widely used in: aerospace gyroscopes; crankshaft balance of racing engines; chassis counterweight of large diesel engines They are widely used in: aerospace gyroscopes; crankshaft balancing for racing engines; chassis counterweight for large diesel engines; vibration generating function in cell phones or game consoles; professional tungsten alloy dart markers, golf head counterweights; downhole logging instruments and various precision optical instruments counterweights, etc.

2. Tungsten copper alloy contains 6~50wt% copper, which has the advantages of both tungsten and copper: high temperature resistance, arc ablation resistance, high strength, high specific gravity, good electrical and thermal conductivity, small thermal expansion, easy cutting and processing, and sweating and cooling characteristics, high temperature resistant gas ablation parts, such as various engine parts, can withstand the strong scouring and thermal shock of high density gas flow; resistant to high Mach speed pneumatic ablation parts, such as leading edge It can resist oxidation and ablation for a long time, so it is widely used in aerospace industry.

3. Tungsten nickel-iron alloy is mainly used in the manufacture of gyroscope rotors, guide devices and shock absorbing devices for aviation and spacecraft; die-casting dies, tool clamps, boring bars and automatic watch hammers for machinery manufacturing; armor-piercing bullet cores for conventional weapons, rivet heads and switch contacts for electrical products; in addition, it is also used in the manufacture of various shielding parts against rays, etc.

TZM molybdenum alloy is mainly used for high temperature components in aerospace technology, such as rocket nozzle throat lining, flight rudder cleats, etc.

4. Molybdenum alloy is very versatile, because it has many characteristics, such as high strength (2000 ℃), low coefficient of thermal expansion, excellent thermal and electrical conductivity, high corrosion resistance to molten glass, molten salt and molten metal, can also improve the wear resistance of thin coatings.

5. Tungsten alloy processing parts, for ships, aircraft, automobiles, cell phones, golf balls, skis, fishing pendants, cranes, alarm clocks and other products counterweight parts. As shielding parts, such as radiation-proof doors, rooms, walls, radiation-proof containers, medical collimators, cell phone shielding parts, nuclear radiation shielding materials, etc.

6. Molybdenum fund high specific gravity processing parts can improve corrosion resistance, increase high temperature strength and improve weldability. It can be seen that molybdenum has an extraordinary role in the steel industry.

Product classification.

1. Tungsten-nickel-iron alloy is an alloy based on tungsten (about 90-98%) and adding nickel, iron, copper or other components, with a specific gravity of 17.0 to 18.5.

2. Tungsten-copper alloy is an alloy composed of tungsten and copper. Commonly used alloy of copper content of 10% to 50%. The alloy is made by powder metallurgy method and has good electrical and thermal conductivity, good high temperature strength and certain plasticity. At very high temperatures, such as above 3000°C, the copper in the alloy is liquefied and evaporates, absorbing a large amount of heat and reducing the surface temperature of the material. So this kind of material is also called metal sweating material.

3. TZM molybdenum alloy is a molybdenum alloy containing 0.4~0.6%(wt) titanium, 0.08~0.12%(wt) zirconium and 0.02~0.03%(wt) carbon, also known as molybdenum-titanium-zirconium alloy. Titanium and zirconium in the alloy both play a solid solution strengthening and carbide dispersion strengthening, and the composite titanium-zirconium carbide is more stable at high temperatures than titanium carbide alone, so the TZM molybdenum alloy has better high-temperature strength and higher recrystallization temperature.

4. Tungsten based high specific gravity machined parts are a class of tungsten based (tungsten content is 85%~99%) alloy with the addition of nickel, iron, copper, cobalt, molybdenum, chromium and other elements, and its density is as high as 16.5~19.0 g/cm3. tungsten based high density alloy is widely used in aerospace industry, weapon industry and civil industry because of its excellent characteristics.

5. Molybdenum alloy is a non-ferrous alloy composed of molybdenum as the base and other elements. The main alloying elements are titanium, zirconium, hafnium, tungsten and rare earth elements. Titanium, zirconium and hafnium elements not only play a solid solution strengthening role for molybdenum alloys to maintain the low temperature plasticity of the alloy, but also to form a stable, diffuse distribution of carbide phase, to improve the strength and recrystallization temperature of the alloy.

6. Tungsten alloy is a class of tungsten-based (containing 85% ~ 99% tungsten), and the addition of a small amount of Ni, Cu, Fe, Co, Mo, Cr and other elements of the alloy, its density up to 16.5 ~ 18.75g/cm3, is commonly known in the world as high specific gravity alloy, heavy alloy or high density tungsten alloy.

7. Molybdenum is a hard, non-magnetic, chemically stable refractory metal with a melting point of 2620°C. At high temperatures, molybdenum can become a very hard metal. At high temperatures, molybdenum becomes oxidizing, being slowly oxidized at 520°C, and rapid oxidation begins to occur above 600°C. At room temperature or at less high temperatures, molybdenum is stable in air or water.

Hongjia is located in the non-ferrous metal processing base - Baoji. Being in the birthplace of metals in China in the 1950s, it has gathered talents and advantages of tungsten, molybdenum and other refractory materials for deep processing, and has strong manufacturing capacity. Hongjia specializes in the production of tungsten, molybdenum, tantalum and other metal refractory material products. The products are used in semiconductor, aerospace, medical equipment, military and other fields.

After more than ten years of development, from a trading company with no reputation, it has developed into a high precision machining center with dozens of sets and domestic ultra-precise testing instruments. Adopting >99.95% high purity raw materials and excellent processing technology, the finished products are made with high density, uniform organization and accurate precision, which have been praised by customers. And we have established trade relations with many countries such as Western Europe, North America, Japan and Australia!

Nowadays, Hongjia has excellent processing ability and has shown excellent ability in terms of cost performance for large volume purchase orders in China, and has been praised by the giant of the pulling crystal industry - Longji!

Hongjia will stand on the customer's point of view and struggle for life to help customers achieve value!

Hong Yali

576521475@qq.com

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.